Uhren-Werke-Dresden

Ein Unternehmen der Tempus Arte Gruppe

Production

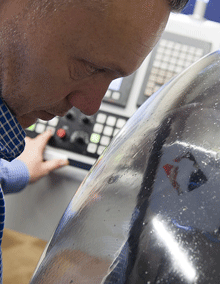

Micro manufacturing meets craftsmanship

Modern CNC turning machines · All production sizes

- Swiss Nano

- Evo Deco 10

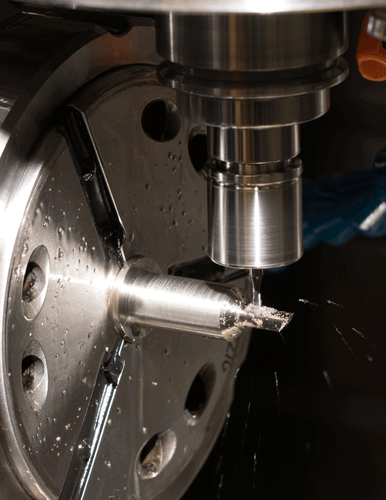

- Almac CU 1007 – 5-axis milling centre

- Bumotec S191 – 7-axis turning and milling centre

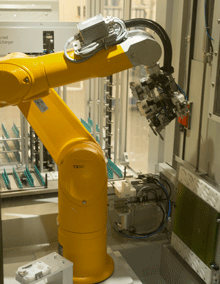

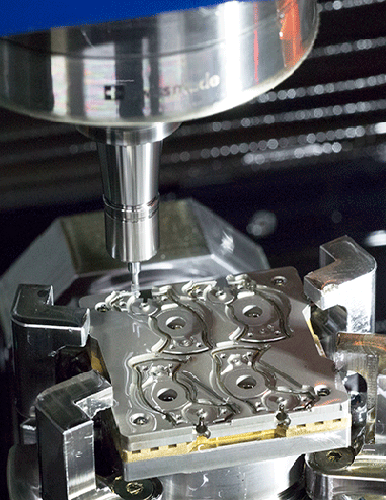

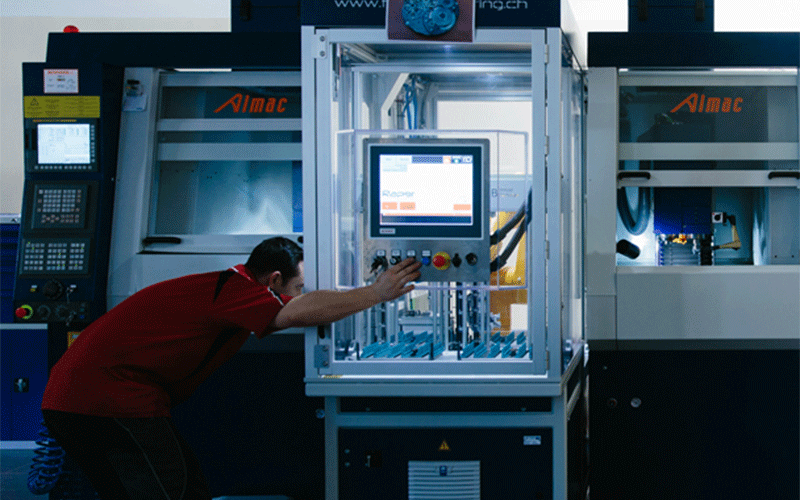

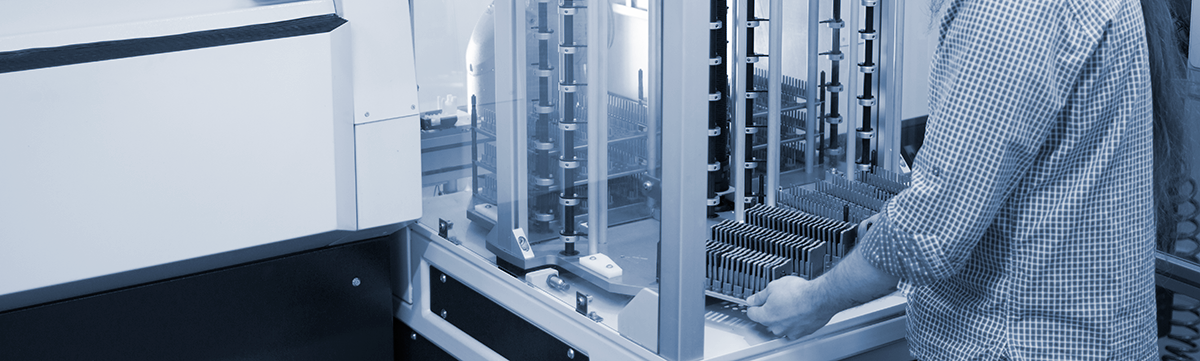

Almac CU 1007

Pick and Place · Flat or milled parts

The Almac CU 1007 CNC processing centre is equipped with a total of two work booths, each with options for 3 to 5-axis processing. Between these two is located a Stäubli robot cell that can rotate, load and unload workpieces for processing with “Pick and Place”. This machine is intended for the manufacture and finishing of flat or milled parts such as springs, levers, plate parts, brackets and bridges.

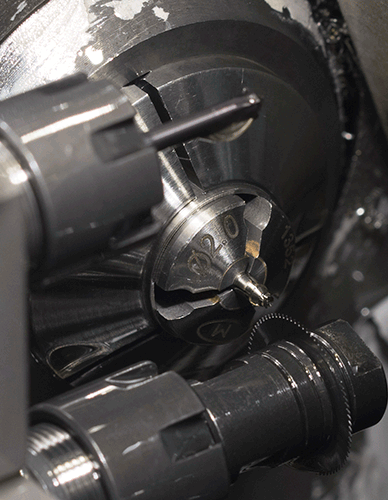

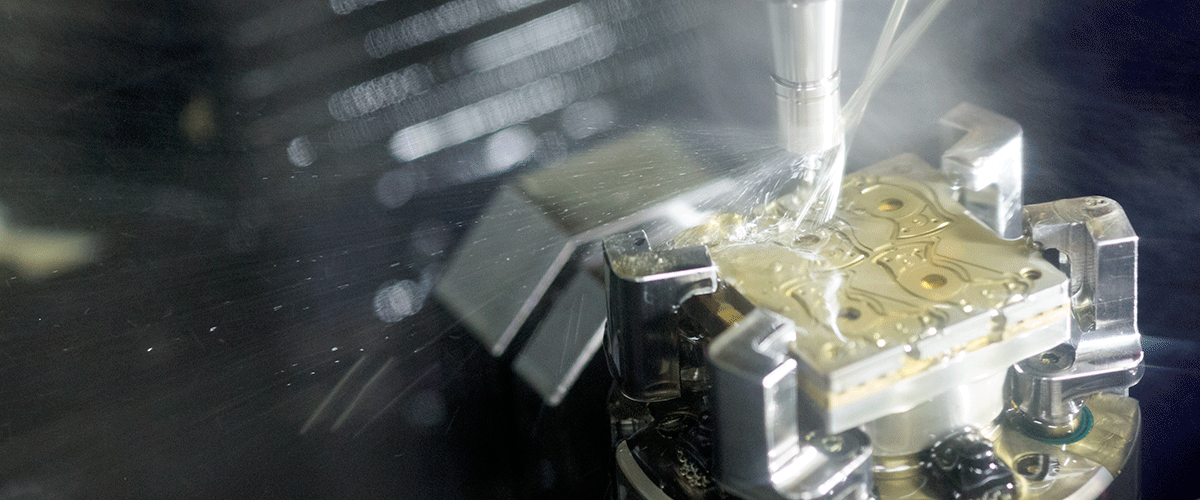

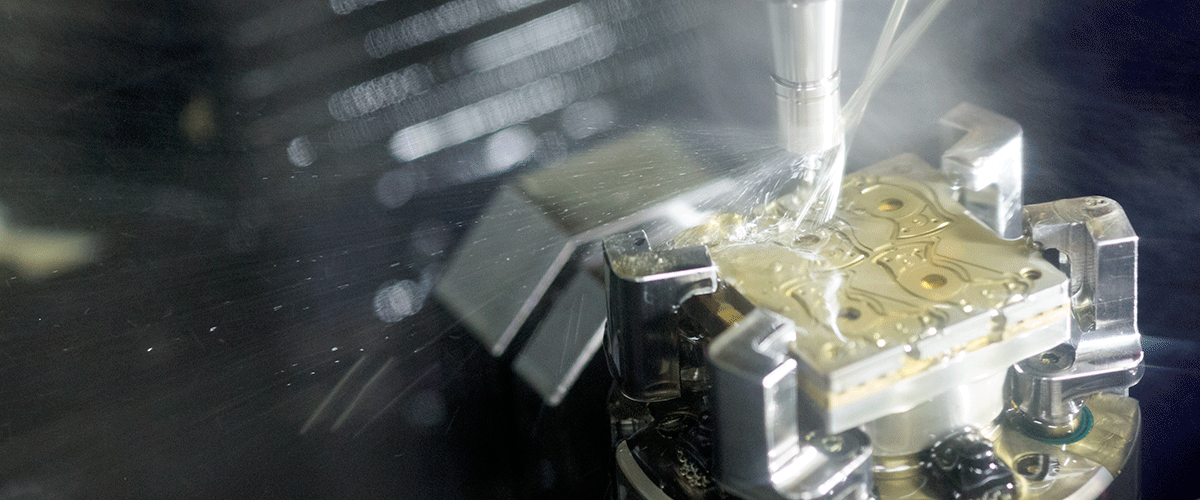

Bumotec S191

Complex components · High precision

Precise and complex components can be manufactured using 7-axis processing with the CNC turning and mailing centre. Thanks to its very robust mechanical design and linear drive technology, accuracy of a few micrometres (<3 µm) can be achieved. An integrated, individually adjustable automatic unit permits the production of prototypes. Moreover, with the aid of LNS bar feeders and a robot cell with “Pick and Place”, this design offers the option of fully-automated long production runs.

EvoDeco 10

Very flexible · Simultaneous processing · Fully automated production

Thanks to its exceptional flexibility, the most complex parts can be produced on this and despite that it is quick to reconfigure. The long automatic lathe has a total of 20 tools including up to 10 powered and 8 milling or drilling tools etc. Simultaneous processing with 4 tools (3 in the main processing direction and 1 in the opposite direction) offers the fully automated production of complex small parts of up to a max. diameter of 10 mm or other high-precision parts.

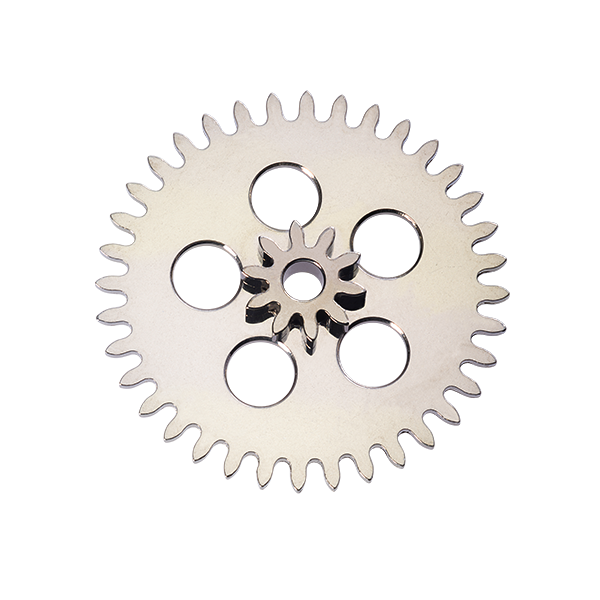

SwissNano

Smallest parts · Excellent quality surface finish

This long lathe is used for processing the smallest parts with micro-precision. With its kinematics, for instance, 2/3 of the parts of a clockwork movement can be produced, from simple to very complex parts such as winding stems, including for example gear milling for sprockets, with excellent quality surface finish. But it can be used not only for watch manufacture but anywhere where the highest quality and precision are required.