Uhren-Werke-Dresden

Ein Unternehmen der Tempus Arte Gruppe

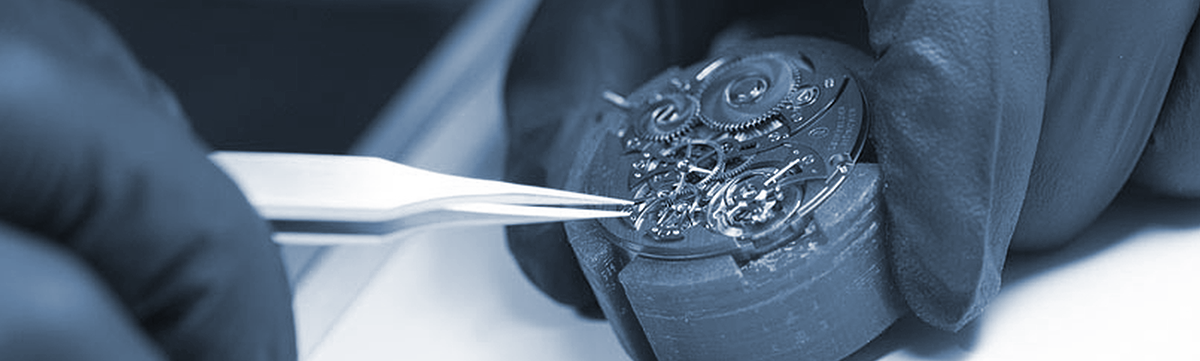

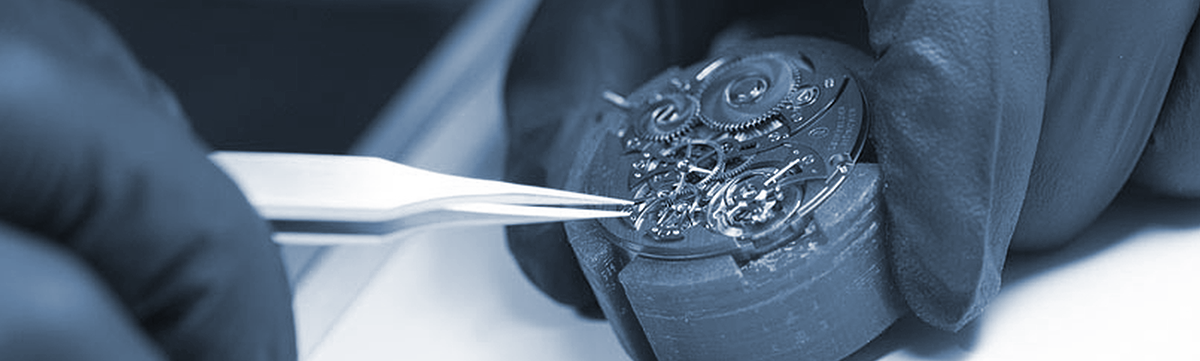

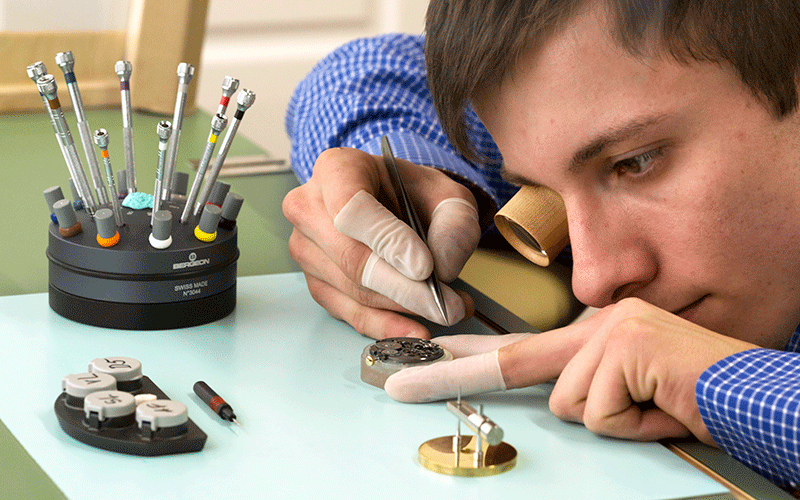

Assembly

Tradition meets innovation

High quality standards · Elaborate sublimations

On their way to becoming masterpieces, UWD’s clockwork movement parts go through two major stages – pre-assembly and final assembly.

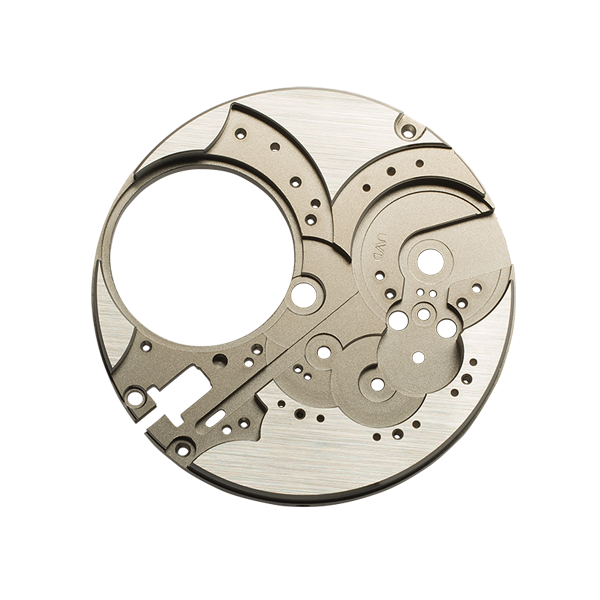

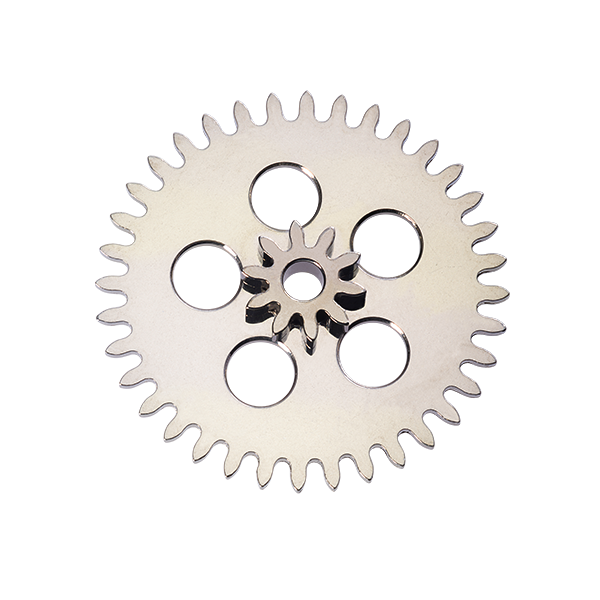

During pre-assembly, the complex mechanisms of the overall movement are perfectly tuned to each other. Once our high quality standards have been met, the movements are completely dismantled again to allow the delicate components to be cleaned and to be finished to a high quality with fine patterning, engraving or polishing.

Detailed precision

Final assembly · Quality tests · Masterpiece

Once the filigree parts have been turned into aesthetic masterpieces in the Finishing department, the calibre is reassembled. The parts are pre-sorted into assembly kits and fitted as subassemblies. Running precision and running behaviour are checked and adjusted as early as in final assembly.

The fully-assembled movement is passed to the experts of Fine Adjustment and adjusted in five stations.